1:500 Architectural models can be sculptural or highly detailed expressions depending on the design, materials and the desired techniques used. This journal aims to highlight some opportunities when working at this tiny scale.

1:500 timber models

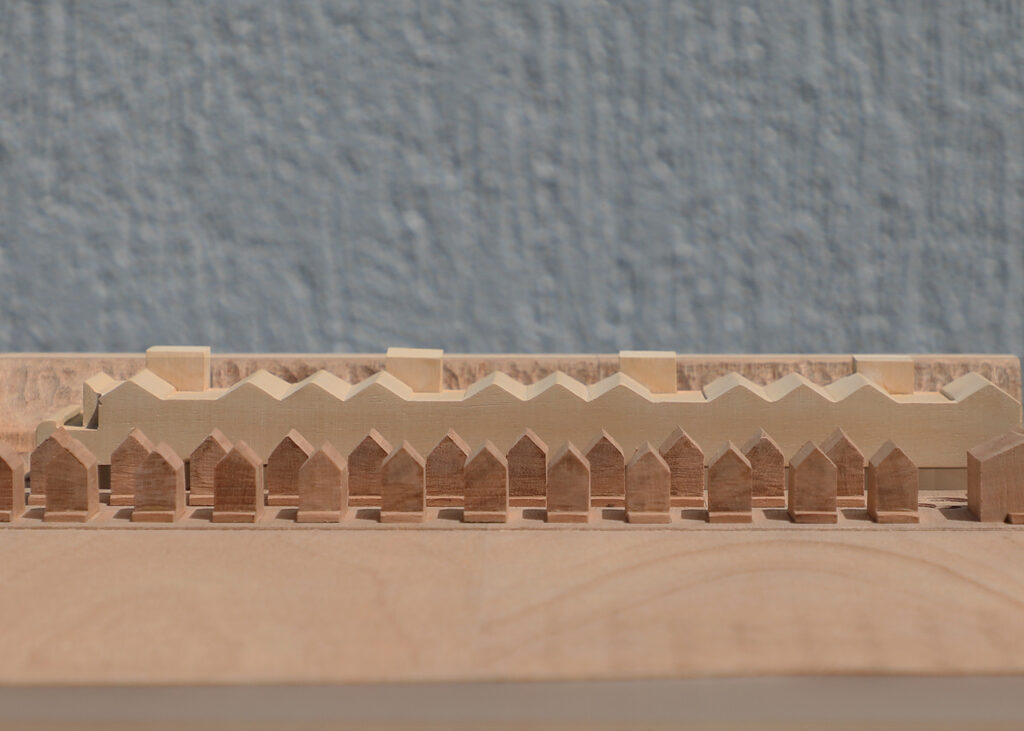

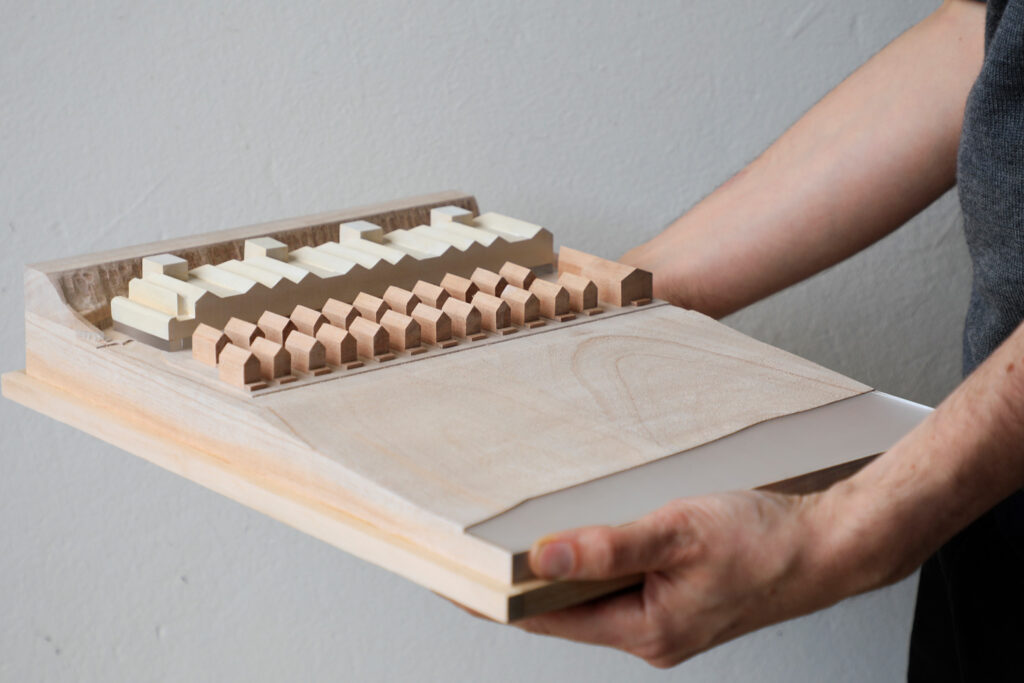

When making 1:500 timber models we use varied techniques such as CNC milling, manual cutting, using blades, ban saws and laser cutting. Each of these model making techniques generate different expressions for both the form and the surface treatment translating architectural details differently. The CNC is amazing for burn free cutting, 3D carving of forms that are more sculptural and for site models but its not appropriate for many finer detail works at this scale as the elements are too small.

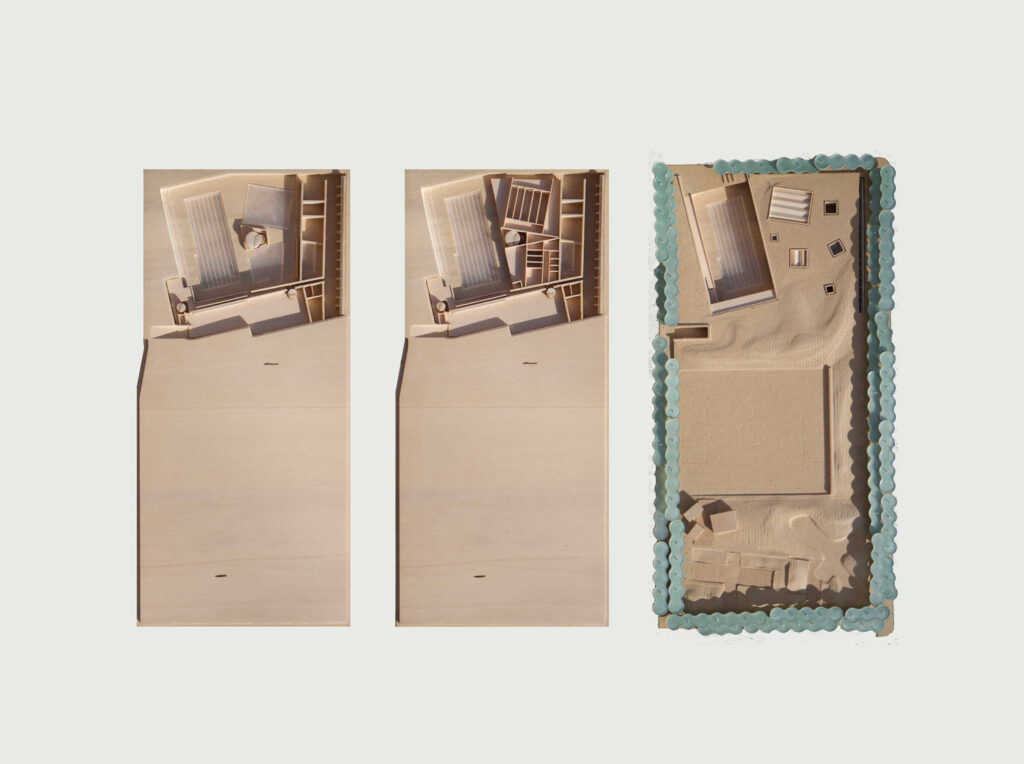

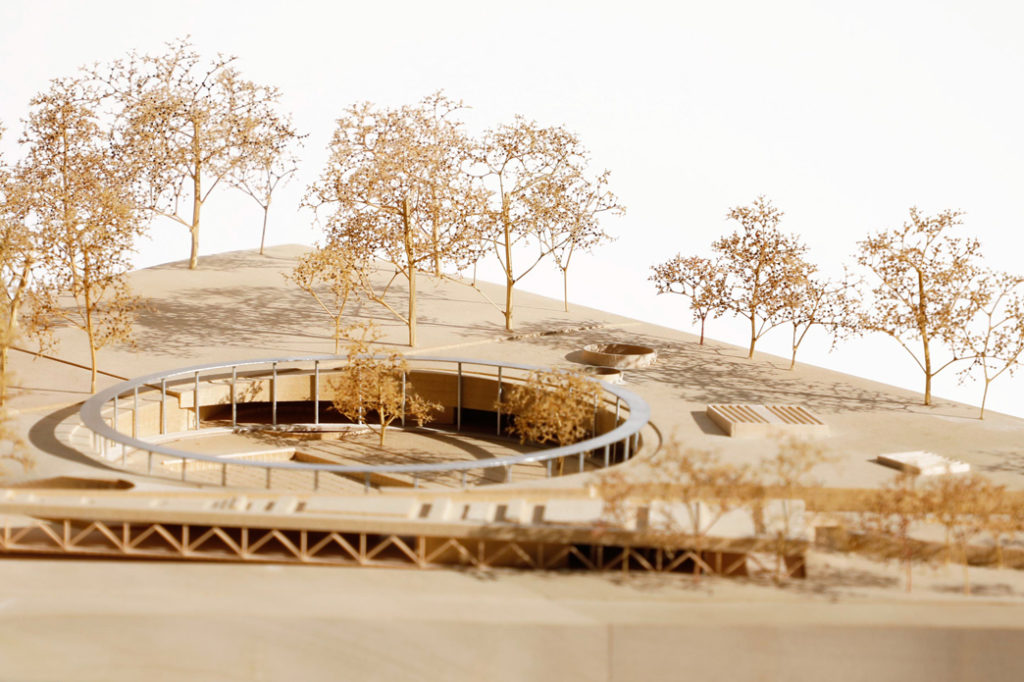

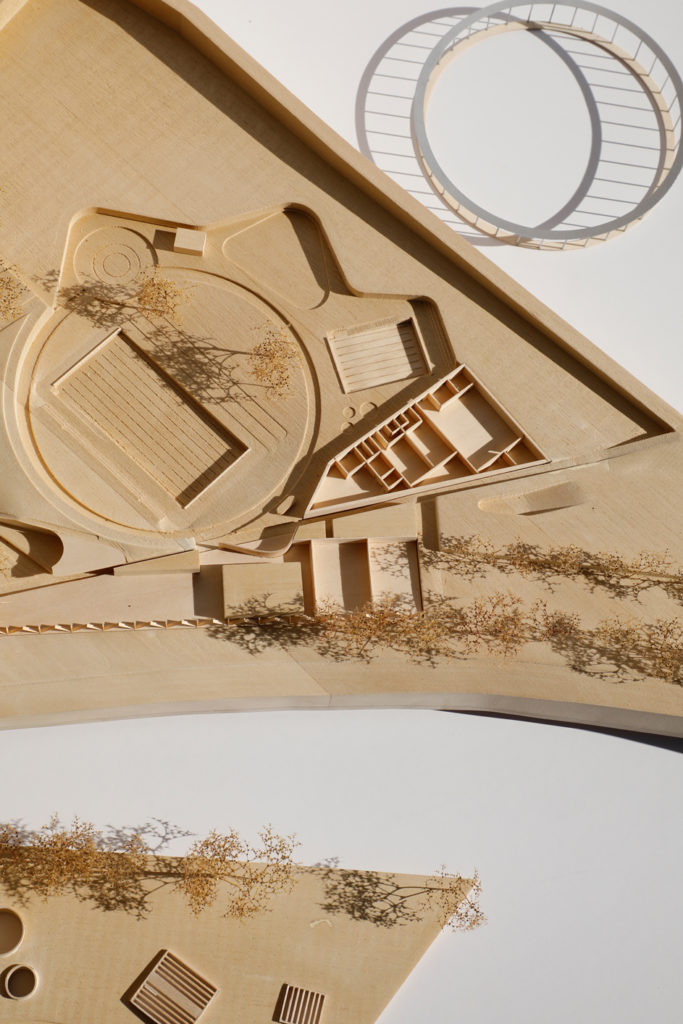

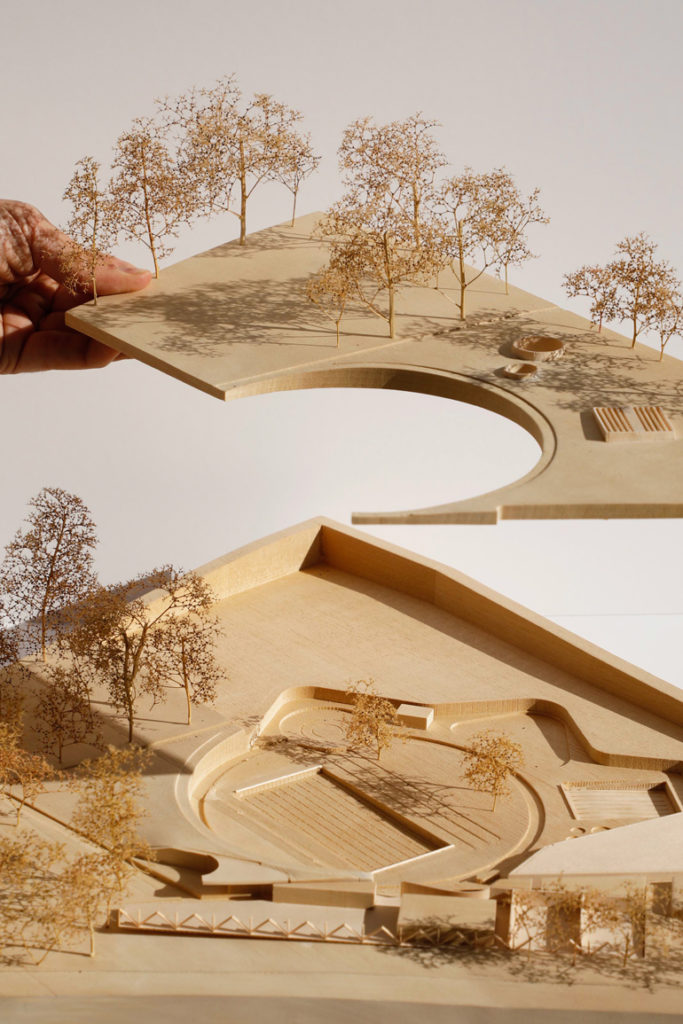

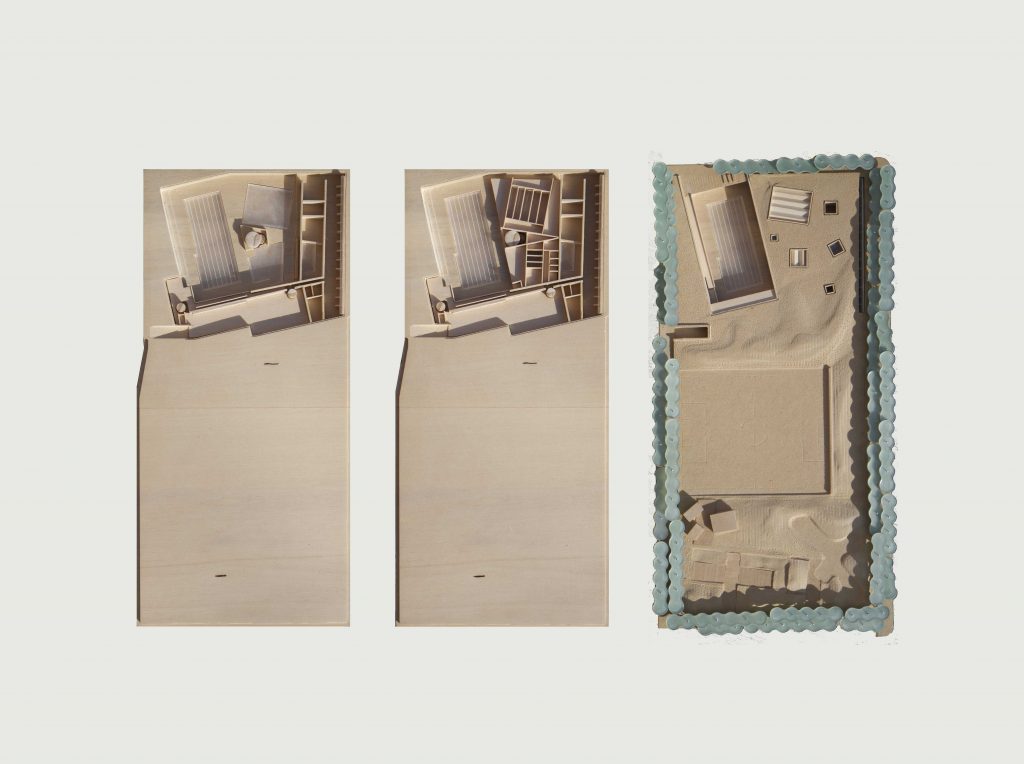

Smart Design Studio & Co-AP’s design for Green square uses CNC milling and hand assembly to craft formal representations of the designs that then slot into a reusable context model. The entire model is made of Solid wood.

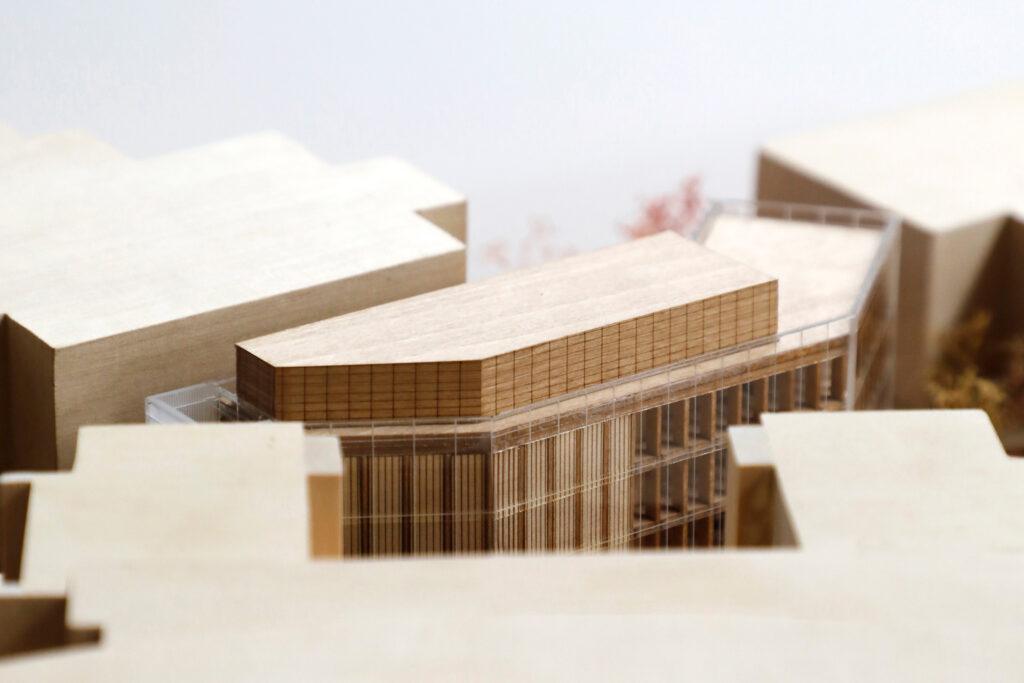

Grimshaw & Andrew Burges design for Parramatta Pool uses a combination of CNC milling and laser cutting to represent building components and pools that are sunken under the landscape. Robust site elements were CNC milled while the model delicate pieces were laser cut and assembled by hand.

1:500 Timber and Acrylic models

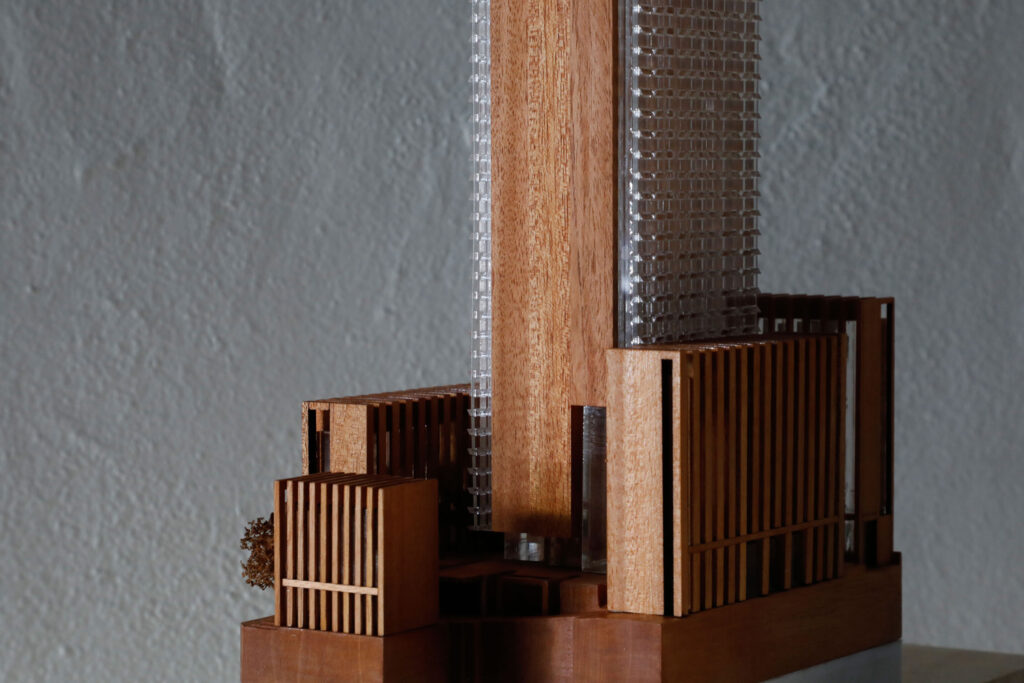

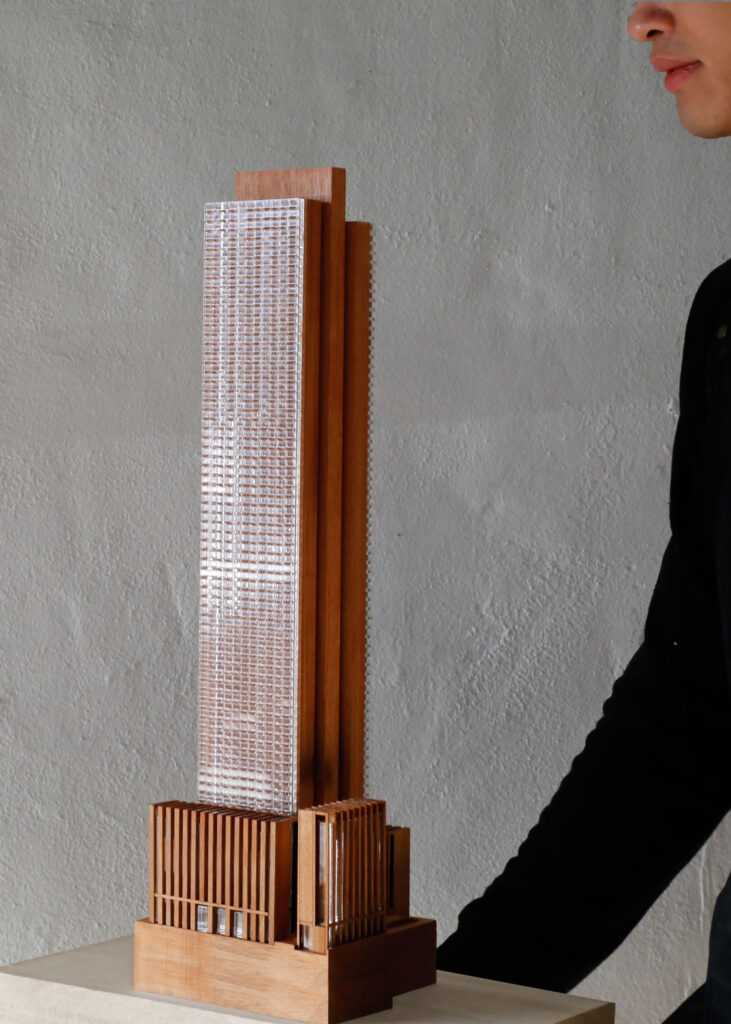

Grimshaw + Smart Design Studio + Panov Scott, 338 Pitt Street uses solid mahogany that has been hand carved, laser cut and assembled. A shimmery acrylic facade was used to express the louvered glazing wall on either side of the building’s design.

Winning Competition entry for BVN and SHOP Architects uses mixed timber and acrylic materials. We utilize rapid fabrication techniques such as resin 3D printing, CNC machined timber and laser cutting.

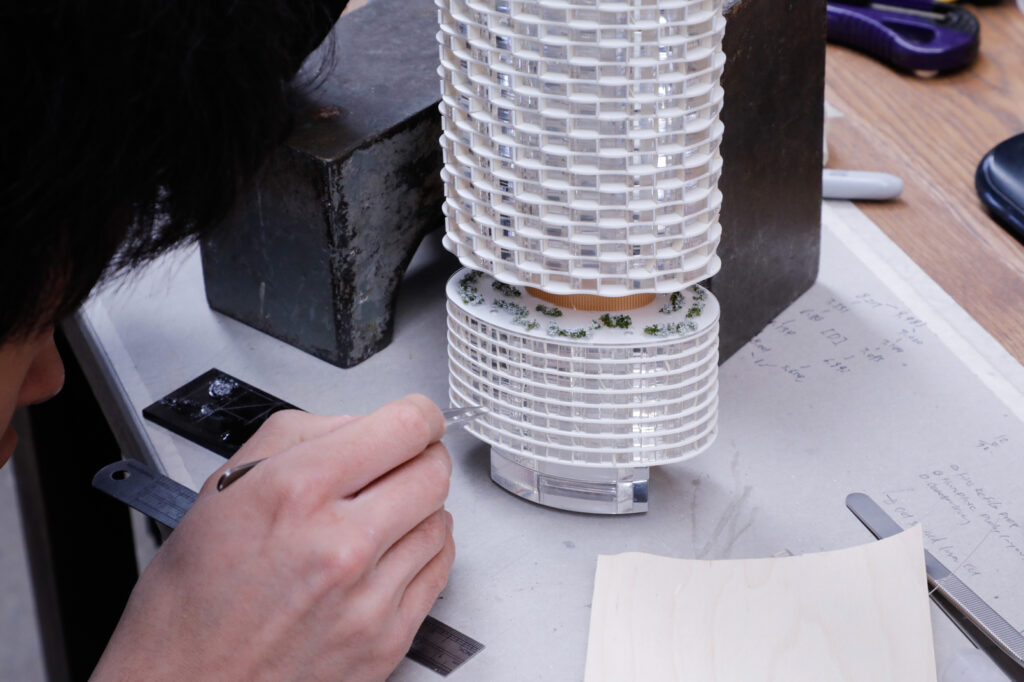

This 1:500 Competition model for CRONE + Kohn Pedersen Fox Associates boasts a delicate facade on both the podium and tower. Acrylic floor to floor construction was used with fine paper details and a sleeve like facade system was applied to the the lower levels. The model would slot in and out of a larger site model.

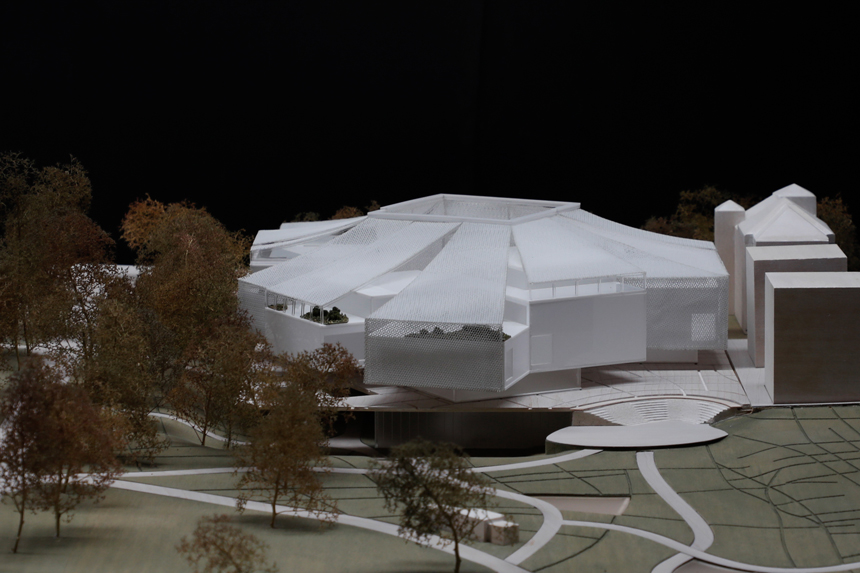

CO-AP’s circular designed form was constructed using resin which was frosted to represent the curtain like skin that in reality, comes alive at dusk with projections and lighting techniques. A solid timber base was carved for CO-AP well before the design was finalized so that the team could test various iterations of the pavilion before locking in the final design which we then molded and fit to the existing base.

1:500 Acrylic Models

Acrylic site models can be lightweight and robust. The surface finish is smooth and can be painted to the desired effect which makes it a versatile material to use. Architecture designs that are made using acrylic fabrication techniques can express a high level of detail when 3D printed or communicate transparent qualities for glazing elements when using acrylics. Similar levels of details can be achieved when combining 3D printing with laser cut techniques for intricate facade systems..

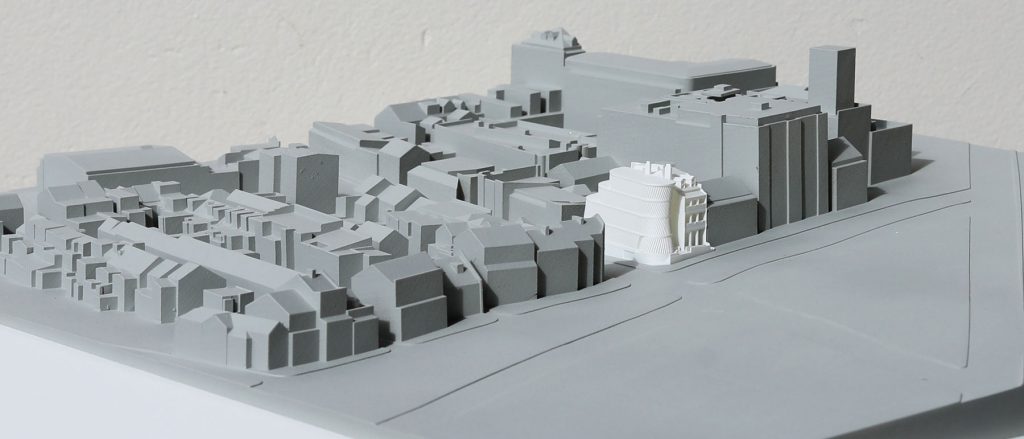

Architectural scale model for City of Sydney for Smart Design studio.